| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Yuhong

Model Number : ASTM A335 P22

Certification : ABS, BV, DNV, CCS, LR

Place of Origin : China

MOQ : 100KGS

Price : Negotiable

Payment Terms : TT,LC

Delivery Time : 7DAYS

Packaging Details : Ply-wooden Case /Iron Case/ Bundle with plastic Cap

Material : ASTM A335 P22

Fin Type : High Frequency Welding

Fin Material : 11-13CR

Application : Furnace

Fin Thickness : 0.8-3mm

Heat Transfer Efficiency : Excellent

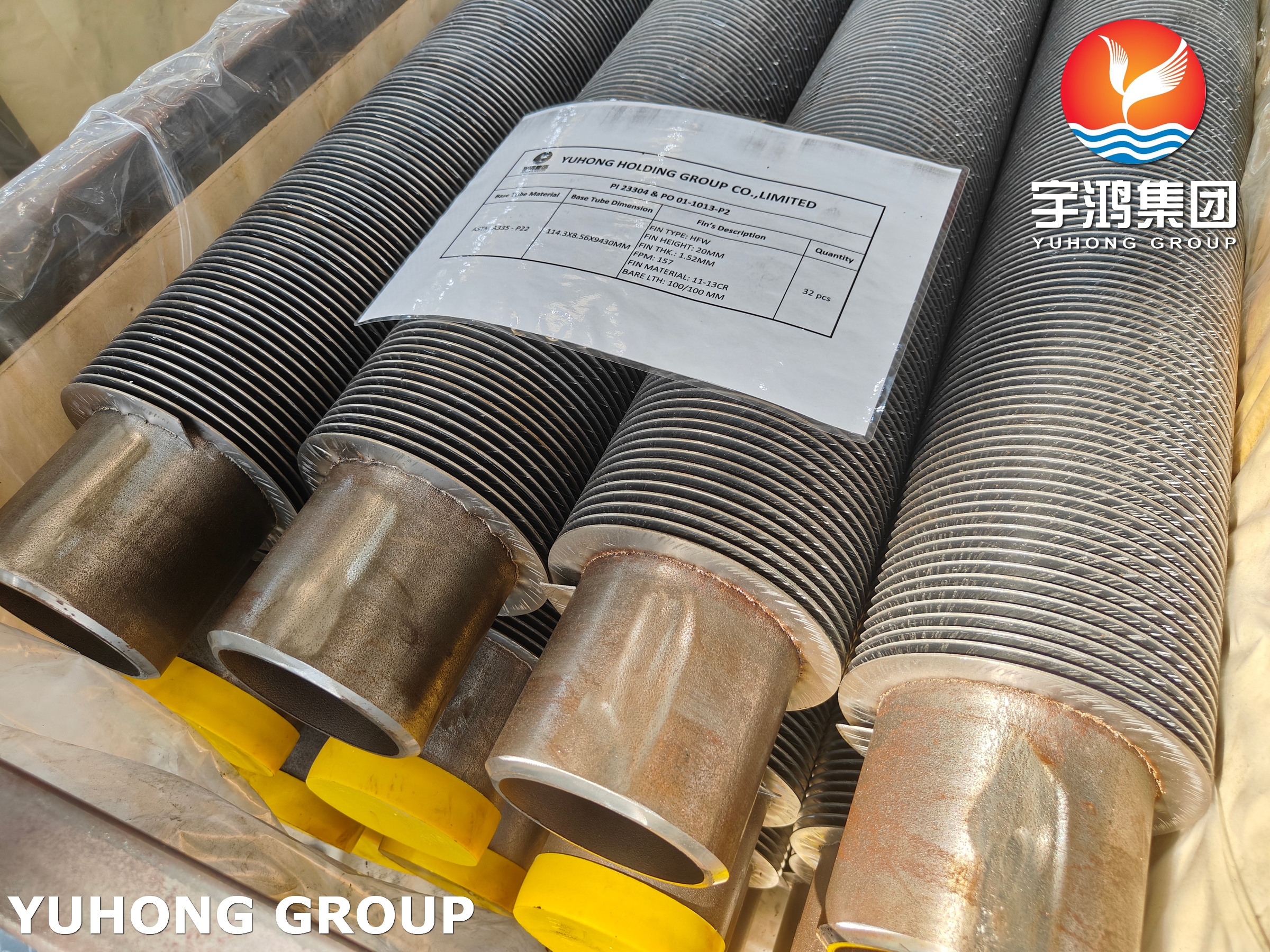

Alloy Steel High Frequency Welding Fin Tube ASTM A335 P22 11-13Cr Fin For Furnace

|

|

Alloy Steel High Frequency Welding Fin Tube ASTM A335 P22 11-13Cr Fin For Furnace Images |